Machine data

Document

Keine weiteren Dokumente vorhandenTechnical details

| Number of sanding units | 2 st. |

| sanding width | 190 mm |

| Sanding height max. | 4-150 mm |

Videos

Additional information

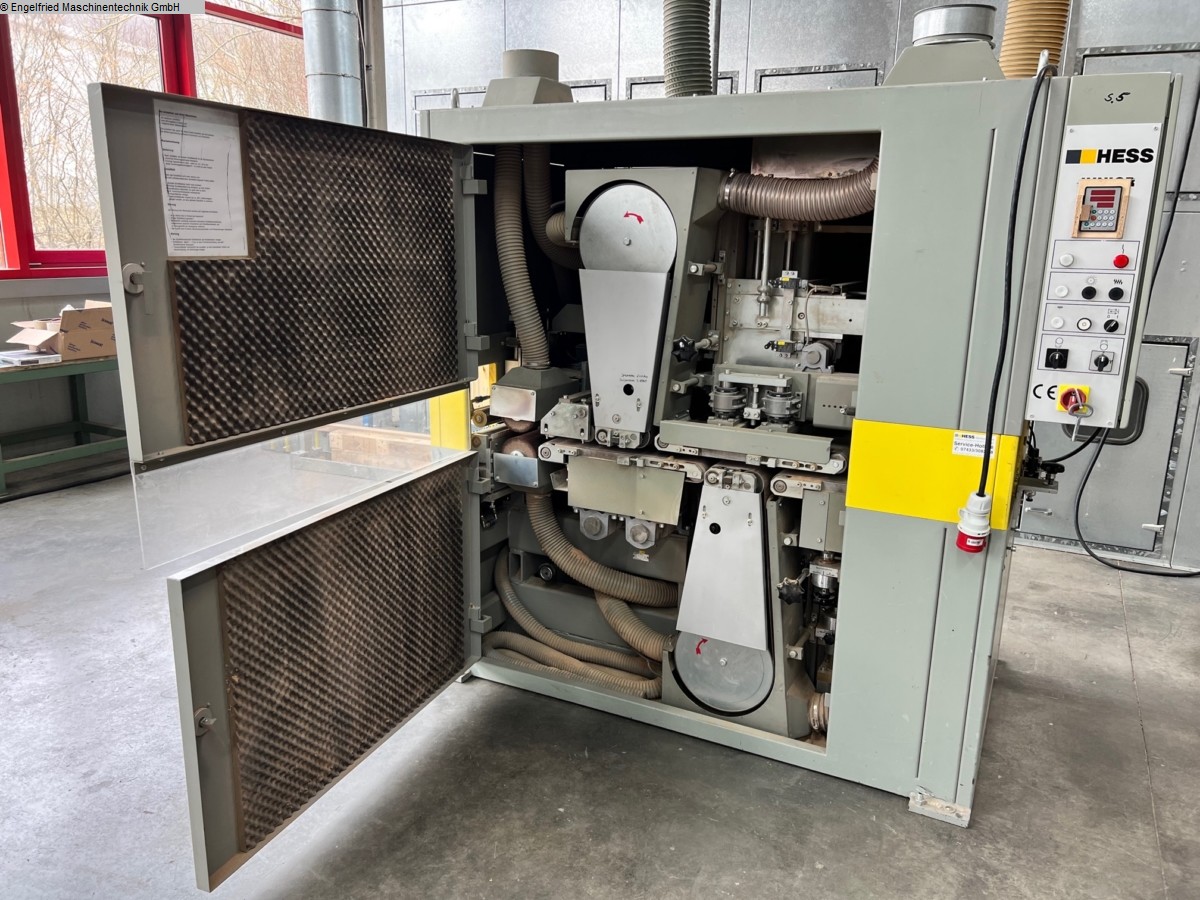

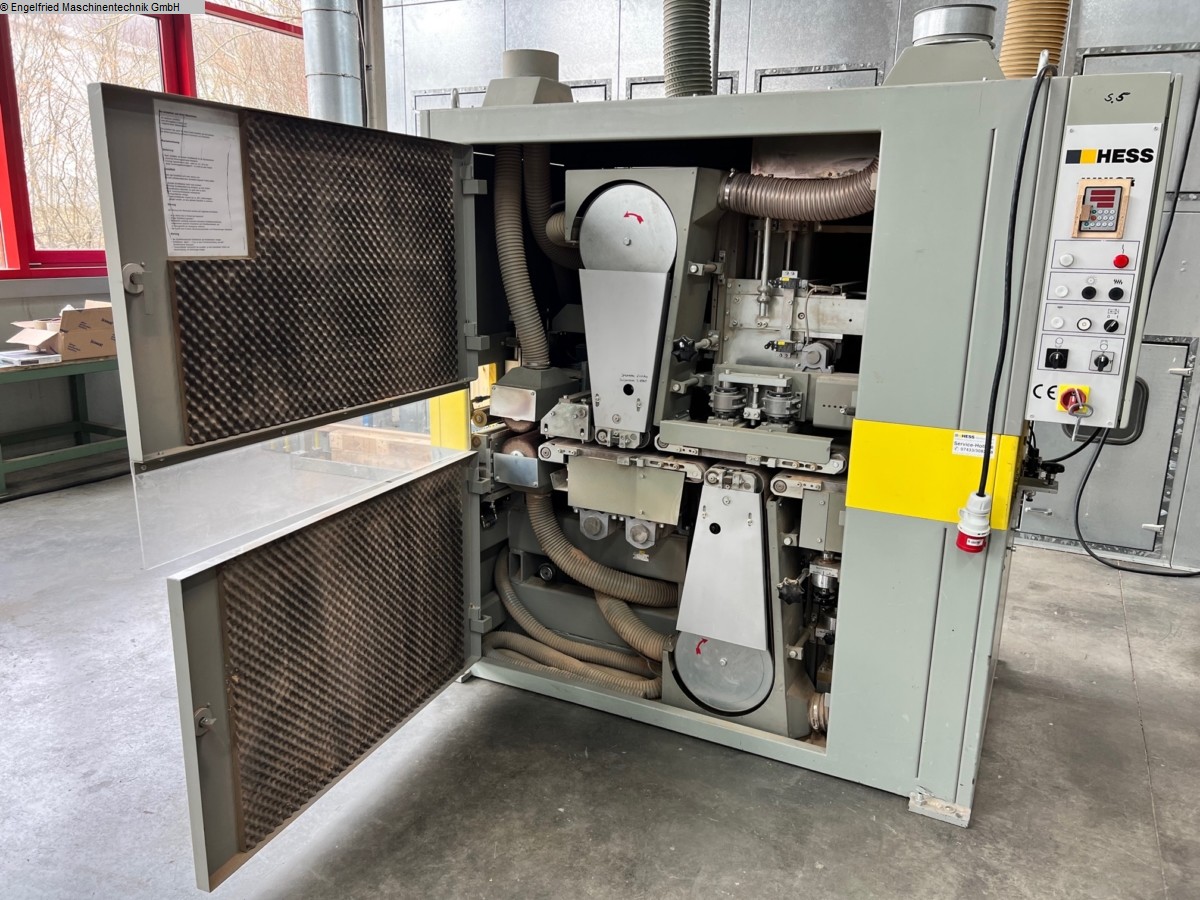

Hess Junior single wood sanding machine

--------------------------------

Machine in checking process at the moment!

Basic structure:

Stable, heavy welded construction made of thick-walled rectangular hollow

profiles with additional, statically calculated reinforcements for optimal

Vibration dampening.

Staggered grinding units with large dimensions

Belt drive drums for slip-free belt running. Two-point suction for direct

and airborne dust extraction with integrated blow-off device. grinding units

in heavy steel plate construction as the basis for vibration-damped,

quiet tape running. All guides as a ball linear set on hardened and

polished waves. Permanent precision thanks to dust and dirt protection

the ball linear sets. Contact roller and sanding pad in a balanced ratio

for sanding belt grain load. The large-sized drive drums

guarantee the full transmission of the 5.5 kW drive power

Grinding motors on the sanding belt. This results in the greatest chip removal

possible. Automatic machine stop activation in the event of a belt break.

Optical display

on control panel. Sanding shoe for finish made of special material with optimal

Heat dissipation and additional sliding coating. Easy to handle

Pad change. Sanding belt tension over appropriately sized

Compression springs. Sanding belt relaxation for belt changing using pneumatic

Device for sensitive, distortion-free placement of new tapes. Upper

Grinding unit and brush device (additional equipment) centrally motorized

adjustable.

Wooden guide in the inlet area for hard guide and bearings mounted on both sides

pressure rollers. Tip-proof transport of profiled workpieces

Calibrated conveyor belts with infinitely adjustable

feed rate.

Automatic machine stop triggering by wood thickness control device.

Visual display of the control panel.

Inlet table via fine-running, precise threaded spindle for lower

Grinding chip removal can be adjusted manually using a scale (resolution 0.1

mm). The length

Column table guide guarantees absolute parallel adjustment. The

The flight circle is coordinated with the exit table by adjusting the height of

the lower one

Grinding unit via precise threaded spindle and scale display (resolution 0.1

mm) accomplished.

Clear, user-friendly arrangement of all electrical functions and operating

and display elements on the front of the machine: grinding unit below,

Grinding unit on top, workpiece transport device,

Grinding thickness adjustment, top/bottom brushing device, belt utilization,

Operating display, fault display. All motors are against overload

electrically protected.

Technical data :

--------------------------------

Sanding belt speed: 25 m/sec.

Grinding width: 190 mm

Grinding thickness: 4 - 150 mm

Shortest workpiece length: 280 mm

Feed speed, continuously adjustable 5 - 25 m/min.

Sanding belt dimensions: 200 mm width, 1850 mm length

Electrical equipment according to VDE

Electrical connection: 400 V., 3/N, 50 Hz.

Pneumatic connection: R 3/8", 6 bar, 80 NL grinding units: 2 x 5.5 kW feed:

0.75 kW Height adjustment: 0.18 kW

Pneumatic connection: R 3/8", 80 NL, min. 6 bar, max. 8 bar Exhaust air

quantity: 2 x

2000 to 2500 m3/h 20 - 25 m/sec.

Suction connection piece: 2 x 180 mm diameter, at the top of the machine housing

External dimensions: without control cabinet 1750 mm width, 1850 mm height,

1000 mm depth

with control cabinet 1960 mm wide, 1850 mm high, 1000 mm deep

Working height: 835 mm

in the range 4-20 mm only without a guide ruler

Paint finish: RAL 7030 stone gray with RAL 1018 zinc yellow

Additional equipment:

1 digital display for motor. Grinding thickness adjustment

1 facility for oscill. Abrasive belt utilization device for oscillating

Utilization of sanding belts to increase the service life of the sanding belts

and improve them

of the surface finish through motor-driven sanding unit adjustment.

Connected load: 0.12 kW, 380 V, 3/N, 50 Hz

1 brushing and finishing device, for better surface finish, integrated in

the basic machine. Two special brush rollers 150 mm arranged one above the other

Diameter in synchronization function for feed. Separate height adjustment

Brush rollers on precise carriage guides for wear correction.

1 pneumatic workpiece release device after brushing and finishing

Furnishings

Included:

1 piece of undriven roller conveyor as an inlet

1 piece of undriven roller conveyor as an outlet (without feets), length

approx. 3 m

VIDEO not original shows machine of the same type

(Technical data according to the manufacturer, no guarantee!)

--------------------------------

Machine in checking process at the moment!

Basic structure:

Stable, heavy welded construction made of thick-walled rectangular hollow

profiles with additional, statically calculated reinforcements for optimal

Vibration dampening.

Staggered grinding units with large dimensions

Belt drive drums for slip-free belt running. Two-point suction for direct

and airborne dust extraction with integrated blow-off device. grinding units

in heavy steel plate construction as the basis for vibration-damped,

quiet tape running. All guides as a ball linear set on hardened and

polished waves. Permanent precision thanks to dust and dirt protection

the ball linear sets. Contact roller and sanding pad in a balanced ratio

for sanding belt grain load. The large-sized drive drums

guarantee the full transmission of the 5.5 kW drive power

Grinding motors on the sanding belt. This results in the greatest chip removal

possible. Automatic machine stop activation in the event of a belt break.

Optical display

on control panel. Sanding shoe for finish made of special material with optimal

Heat dissipation and additional sliding coating. Easy to handle

Pad change. Sanding belt tension over appropriately sized

Compression springs. Sanding belt relaxation for belt changing using pneumatic

Device for sensitive, distortion-free placement of new tapes. Upper

Grinding unit and brush device (additional equipment) centrally motorized

adjustable.

Wooden guide in the inlet area for hard guide and bearings mounted on both sides

pressure rollers. Tip-proof transport of profiled workpieces

Calibrated conveyor belts with infinitely adjustable

feed rate.

Automatic machine stop triggering by wood thickness control device.

Visual display of the control panel.

Inlet table via fine-running, precise threaded spindle for lower

Grinding chip removal can be adjusted manually using a scale (resolution 0.1

mm). The length

Column table guide guarantees absolute parallel adjustment. The

The flight circle is coordinated with the exit table by adjusting the height of

the lower one

Grinding unit via precise threaded spindle and scale display (resolution 0.1

mm) accomplished.

Clear, user-friendly arrangement of all electrical functions and operating

and display elements on the front of the machine: grinding unit below,

Grinding unit on top, workpiece transport device,

Grinding thickness adjustment, top/bottom brushing device, belt utilization,

Operating display, fault display. All motors are against overload

electrically protected.

Technical data :

--------------------------------

Sanding belt speed: 25 m/sec.

Grinding width: 190 mm

Grinding thickness: 4 - 150 mm

Shortest workpiece length: 280 mm

Feed speed, continuously adjustable 5 - 25 m/min.

Sanding belt dimensions: 200 mm width, 1850 mm length

Electrical equipment according to VDE

Electrical connection: 400 V., 3/N, 50 Hz.

Pneumatic connection: R 3/8", 6 bar, 80 NL grinding units: 2 x 5.5 kW feed:

0.75 kW Height adjustment: 0.18 kW

Pneumatic connection: R 3/8", 80 NL, min. 6 bar, max. 8 bar Exhaust air

quantity: 2 x

2000 to 2500 m3/h 20 - 25 m/sec.

Suction connection piece: 2 x 180 mm diameter, at the top of the machine housing

External dimensions: without control cabinet 1750 mm width, 1850 mm height,

1000 mm depth

with control cabinet 1960 mm wide, 1850 mm high, 1000 mm deep

Working height: 835 mm

in the range 4-20 mm only without a guide ruler

Paint finish: RAL 7030 stone gray with RAL 1018 zinc yellow

Additional equipment:

1 digital display for motor. Grinding thickness adjustment

1 facility for oscill. Abrasive belt utilization device for oscillating

Utilization of sanding belts to increase the service life of the sanding belts

and improve them

of the surface finish through motor-driven sanding unit adjustment.

Connected load: 0.12 kW, 380 V, 3/N, 50 Hz

1 brushing and finishing device, for better surface finish, integrated in

the basic machine. Two special brush rollers 150 mm arranged one above the other

Diameter in synchronization function for feed. Separate height adjustment

Brush rollers on precise carriage guides for wear correction.

1 pneumatic workpiece release device after brushing and finishing

Furnishings

Included:

1 piece of undriven roller conveyor as an inlet

1 piece of undriven roller conveyor as an outlet (without feets), length

approx. 3 m

VIDEO not original shows machine of the same type

(Technical data according to the manufacturer, no guarantee!)

On this page you will find a an offer on a used Sanding machine of type Junior of the company HESS with year of construction gebraucht and with stock no.: 1305-2731. The machine is manufactured by the company Engelfried Maschinentechnik GmbH from 73432 Aalen offered. The delivery time / delivery status for this machine is: after arrangement For more information, please refer to the details listed.

Documents & Videos

Keine weiteren Dokumente vorhanden

Machine

Sanding machine